用途 Application

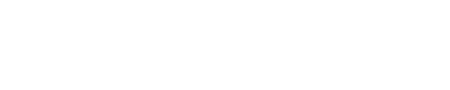

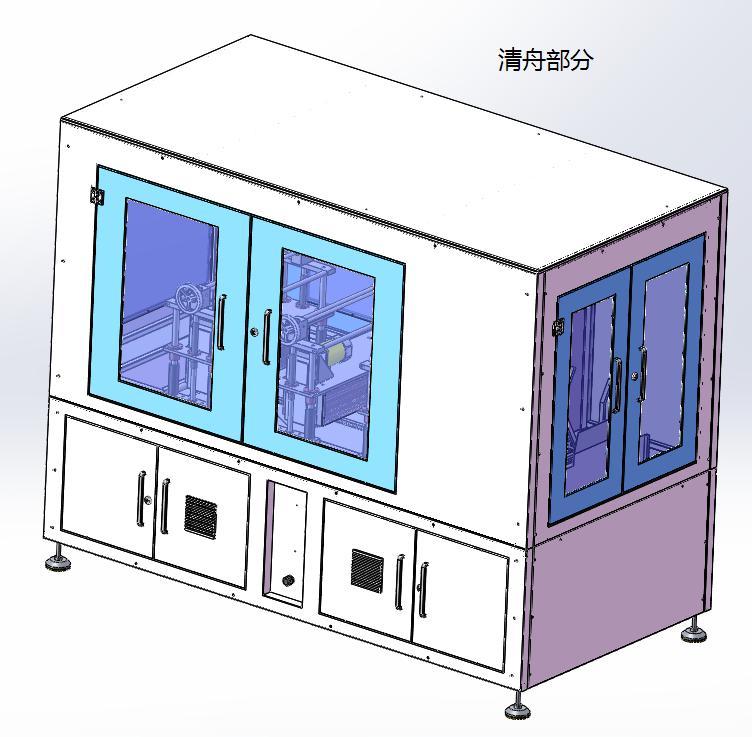

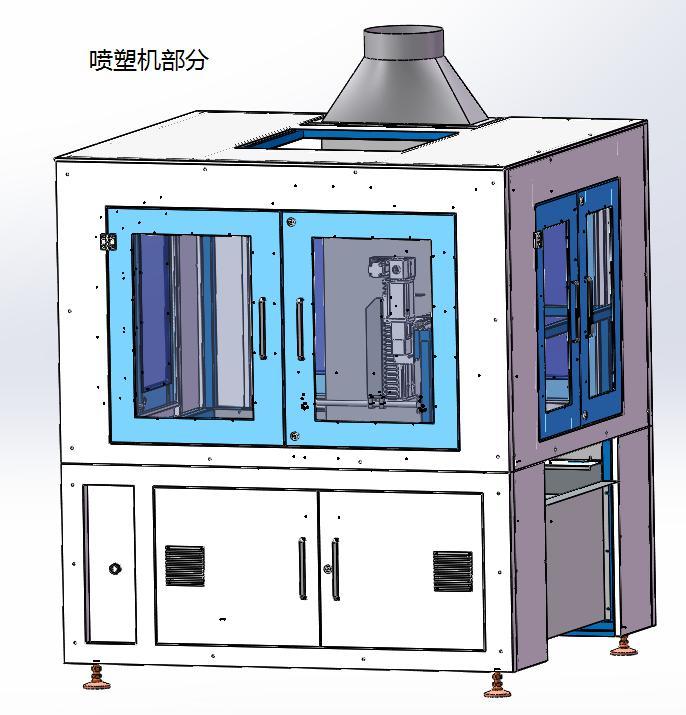

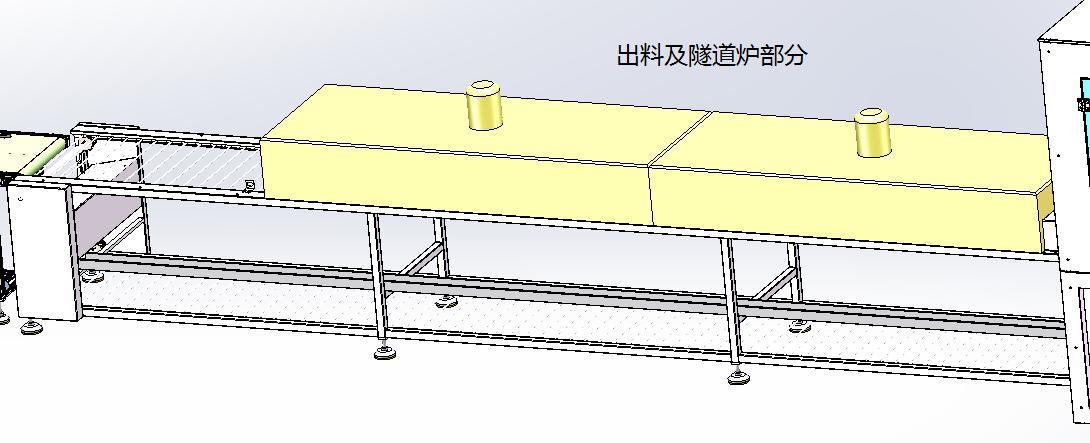

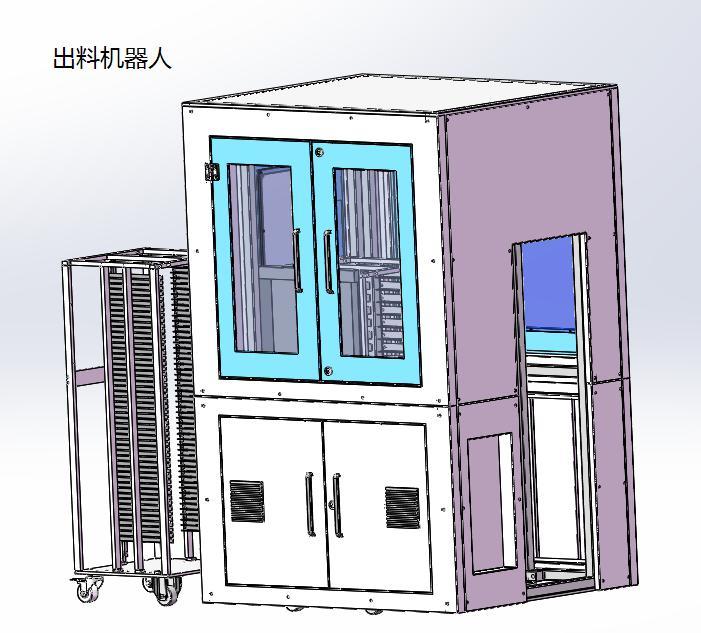

清舟喷塑产线是位于自动粉末压机的前端工艺。主要是将人工实现的清舟、喷涂、烘烤、码垛等融为一台设备,实现全自动工艺。人工只需添加工艺前的舟皿,工艺后可直接取出码垛完的小车,送入下道工序。另可选择AGV小车实现全自动化。

The Clean the empty disc and spray production line are the front-end processes of the automatic powder press. The main purpose is to integrate the manual cleaning, spraying, baking, palletizing, etc. into one equipment to realize a fully automatic process. Manually only need to add the empty plate before the process, after the process, the palletized trolley can be taken out directly and sent to the press. An AGV trolley can also be selected to achieve full automation.

参数 Parameter

|

项目

Project |

规格

Specification |

|

烧结舟皿尺寸

Sintering boat size

mm |

Φ300XΦ45/400X400 |

|

取单盘最大重量

Take the maximum weight of a single plate

Kg |

4.0 |

|

小车装盘数盘/车

Car loaded with several plates/car |

20 |

|

功率

Power

kW |

20 KW |

|

对接效率盘

Docking efficiency disk

/min |

1~3(其换盘速度可设定)

1~3 (The speed of changing disk can be set) |

|

外形尺寸(长X宽X高)

Dimensions (length X width X height)

mm |

14000X2500X1500 |

特点 Features

■设备占地空间小、结构简单、安装、维护便捷、能耗低等优点;

■将多台设备合而为一,简化生产线,性价比高;

■可实现AGV 小车转运(选择功能) ;

■管理系统对接及末端数据统计回馈(留有数据接口);

■可根据技术要求定制开发。

1、The equipment has the advantages of small space occupation, simple structure, convenient installation, maintenance and low energy consumption;

2、The multiple devices into one to simplify the production line, cost-effective;

3、Can realize AGV car transfer (select function);

4、Management system docking and terminal data statistical feedback (retaining data interface);

5、Can be customized development according to technical requirements.

关键词:

上一页

下一页

上一页

下一页